COVID-19 Pandemic

Our Response To The Pandemic

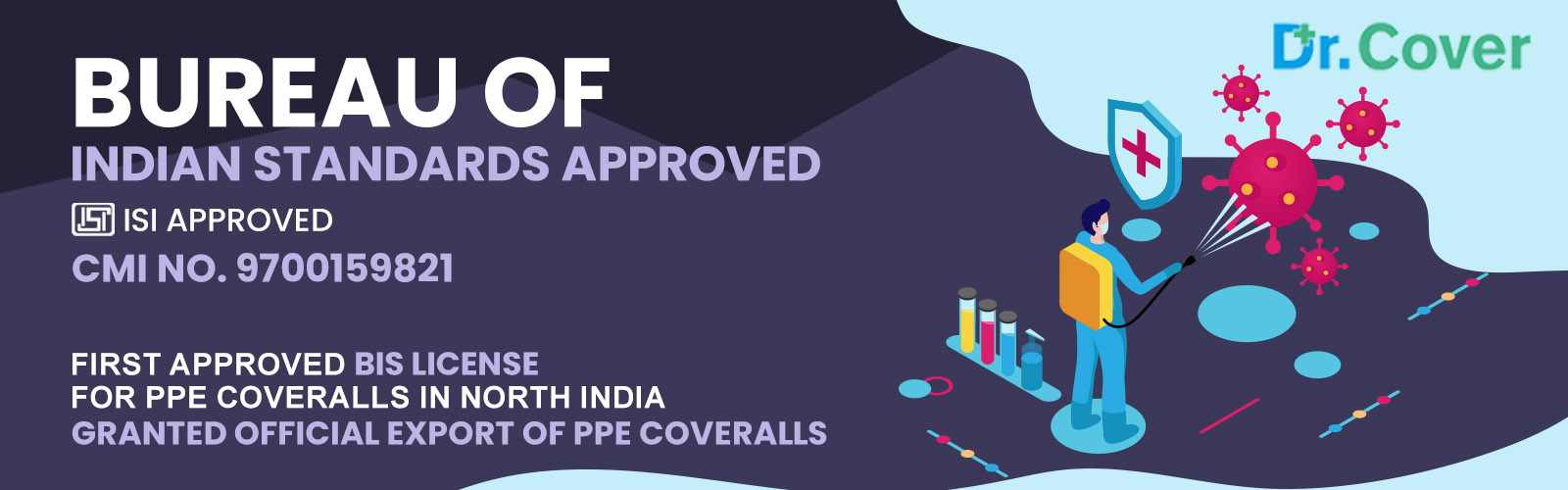

We at Dr. Cover strive to help out as much as we can. This is why we introduce our collection of Personal Protective Equipment for helping out during a global catastrophe like this.

With automatic production units and separate sterilisation units, we guarantee quality, as well as quantity of products to help out as much as possible. Our unique and over the top technologies of these products are made from using a collection of sciences. But that’s not it! We here at Dr. Cover are restless for development and trust, and we know how much it takes to build them up. Our wide team of researchers and designers are set to finding new ways to make you safe while staying comfortable as well. You shouldn’t just have to choose one!

In the end, Dr. Cover understands what it means to be on the frontline fighting and risking your lives on a daily basis. We appreciate everyone who is helping the world during a difficult time like this, and we strive to provide great protection and comfort for everyone.

Latest Blog Posts

Recent from Updates

Apr 12, 2020

Dr. Cover’s

Automatic N95 Respirator Manufacturing Process

Freshly unpacked, our multiple rolls of quality fabric are loaded onto the automatic production machines. Our machines stretch out and insert the fabrics into the production lines individually for no errors.

The machines blend the fabrics together and cut them as per the N95 mask shape being produced. The cutout designs are suitable for both N95 Masks, with and without valves. As per the requirements, the adjustable nose pieces are automatically put inside the mask with extra cushioning.

The machines automatically ascend the mask cuttings into its next component, the edges of the mask are welded together, along with our comfort elastic ear/head straps. This avoids stitching/stapling them into the mask, achieving no penetration.

The welded masks then go to the printing panels of the machines, for printing as per the production requirements. The masks are then folded by the machines itself; inserting the exhalation valves if needed, and are finally cut out of the fabric lines.

The next component of the production is our favourite, our UV-Light Sterilisation Unit, a production standard for us. This sterilises the masks fully, and removes any chances for virus, bacteria, toxins, etc. of being in the products you will use for your protection.

Our Hands-Free Sealed Packing Machines do the remaining like magic. The sealed packaging stores one mask per pack. From our automated machines we achieve production with no human contact throughout the entire production process.